Products

New Products

-

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5

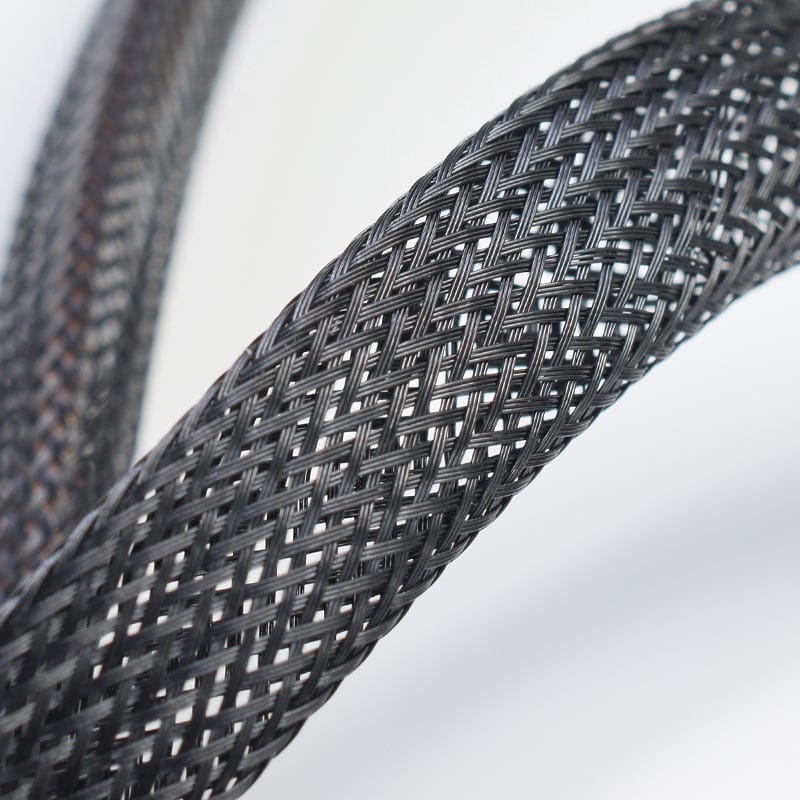

PPS Expandable Braided Wire Sleeving

PPS expandable braided sleeve is made of PPS (PolyPhenylene Sulfide ) monofilament and has the greatest chemical resistance of any advanced engineering plastic. The material is inert to steam, strong bases, fuels and acids. It provides the perfect solution to cables or hoses protection in high-temperature environments.

| Part No | BRS-PPS |

|---|---|

| Material | PPS(PolyPhenyleneSulfide) |

| Monofilament Thickness | 0.08”(0.20mm) |

| Working Temperature | -70℃ to 200℃ |

| Melt Point | 280+(-)10℃ |

| Flammability | VW-1,UL94V0 |

| Standard Color | Black |

| Certification | ROHS, Reach,HalogenFree |

| UV Resistant | Yes |

| Cutting Tool | Hot Knife |

PPS Expandable Braided Wire Sleeving

PPS (PolyPhenylene Sulfide) monofilament forms PPS expandable braided cable sleeve, providing flame-resistant protection for wire harnesses and cable assemblies used in aerospace, military, and other high-precision applications within harsh environments.

The pps wire protector sleeve is a lightweight cable braided sleeve that is extremely flexible. It is UV resistant, has high wear resistance, and is resistant to most oils, fuels, and solvents. Use in high temperatures for working stability.

Certifications

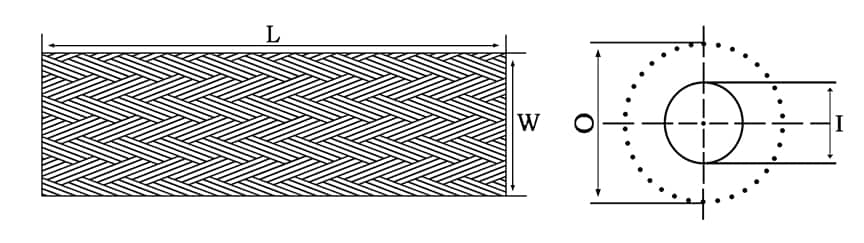

Product Size

| Part No | Size | Expanded Range | Packing | ||

|---|---|---|---|---|---|

| Inch | mm | Min(I) | Max(O) | (m/spool) | |

| BRS-PPS-003-BK | 1/8″ | 3 | 1 | 6 | 1000 |

| BRS-PPS-006-BK | 1/4″ | 6 | 3 | 9 | 500 |

| BRS-PPS-008-BK | 5/16″ | 8 | 5 | 12 | 350 |

| BRS-PPS-010-BK | 3/8″ | 10 | 7 | 17 | 350 |

| BRS-PPS-012-BK | 1/2″ | 12 | 8 | 20 | 300 |

| BRS-PPS-016-BK | 5/8″ | 16 | 10 | 27 | 250 |

| BRS-PPS-020-BK | 3/4″ | 20 | 14 | 30 | 200 |

| BRS-PPS-025-BK | 1″ | 25 | 18 | 33 | 200 |

| BRS-PPS-032-BK | 1-1/4″ | 32 | 20 | 50 | 150 |

| BRS-PPS-038-BK | 1-1/2″ | 38 | 30 | 60 | 100 |

| BRS-PPS-045-BK | 1-3/4″ | 45 | 35 | 75 | 100 |

| BRS-PPS-050-BK | 2″ | 50 | 40 | 80 | 100 |

| BRS-PPS-064-BK | 2-1/2″ | 64 | 45 | 105 | 100 |

| BRS-PPS-076-BK | 3″ | 76 | 64 | 120 | 100 |

Application of PPS Expandable Braided Wire Sleeving

We engineered PPS braided cable sleeving specifically for high-demand applications, providing essential protection for cables in extreme conditions. Race cars, aerospace, telecom, and military sectors commonly use it. PPS sleeving withstands frequent exposure to heat, chemicals, abrasion, and other environmental hazards. This durable sleeving offers reliable performance in environments where resilience is essential. Ideal for applications needing both flexibility and strength, PPS braided sleeving provides optimal protection while maintaining cable organization under rigorous conditions.