When wiring up lights, outlets, or other components under the body of a truck or vehicle, choosing the right cable protection is critical to ensure durability and reliability. Customers often face the dilemma of selecting between braided cable zipper sleeving and split loom, especially when considering factors like environmental exposure to dirt, debris, and the need for neatness and manageability.

We offer tailored solutions that address these concerns and help you make an informed decision based on your project needs.

1.Protecting Underbody Wiring: Braided Cable Zipper Sleeving

Braided cable sleeves offer excellent protection against abrasions, providing a soft yet durable shield for your cables. Our flexible black PET expandable zipper sleeve braided cable wrap is an ideal solution for wiring under the truck body. It provides:

Durability: With superior abrasion resistance, braided sleeves protect wires from dirt, dust, and mechanical wear.

Flexibility: The expandable nature allows it to fit various cable sizes, while its flexibility accommodates movement and vibrations, typical in automotive and off-road environments.

Ease of Installation: The zipper structure allows easy installation, even in tight spaces, and can be opened for quick adjustments.

However, braided sleeves can accumulate dirt and debris over time. To counter this, you can pair the braided sleeves with Braided Wiring Harness Wrap which has a more rigid structure to resist dust ingress while maintaining high flexibility.

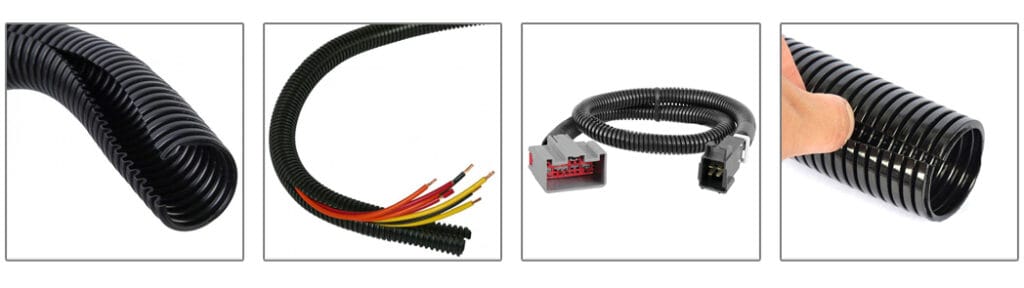

2.Corrugated Split Loom: A Practical Option for External Wiring

Split loom tubing is the go-to choice for factory installations due to its practicality and robust protection.

Pros for Underbody Use:

- Debris Resistance: Its closed structure effectively shields cables from mud and dust.

- Ease of Installation: The split design allows for quick cable insertion and adjustments.

- Durability: Offers excellent protection against environmental wear and tear.

Cons for Underbody Use:

- Rigidity: Less flexible than braided sleeves, which can make it harder to route in tight spaces.

- Bulkier Appearance: May not be as visually appealing.

When to Use:

Corrugated split loom is best for sections directly exposed to dirt, mud, and debris, such as under the frame of the truck.

3.Combining Both Solutions

When running wiring under the body of a vehicle, the challenge is finding a balance between flexibility, protection, and ease of installation. By combining braided zipper sleeving with corrugated split loom, you can create a robust, versatile solution tailored to withstand demanding environments while simplifying your work.

Combining these materials ensures optimal performance across all wiring sections, whether exposed or shielded.

Use Braided Zipper Sleeves for Accessible and Protected Sections

- Install braided zipper sleeves on wiring in areas that require frequent maintenance or are shielded from direct exposure.

- The zipper design allows easy access for future adjustments or inspections without removing the sleeve entirely.

Use Corrugated Split Loom for Exposed and High-Risk Sections

At transitions between braided zipper sleeves and split loom tubing, use heat-shrink tubing, tape, or zip ties to secure the connection and prevent debris from entering.Secure wiring to the vehicle body using cable clamps or adhesive mounts for additional protection and stability.

Its rugged design ensures cables are well-protected from external damage.

Apply split loom tubing on wiring running under the frame or in areas prone to impact, mud, and water exposure.

Ready to upgrade your wiring setup? Explore premium braided zipper sleeving and corrugated split loom products at MJ-FLEX. Let us help you build a wiring solution that’s as tough and flexible as your needs demand!