Customers Have Alternatives — But Why Do They Still Choose a Tight Weave Braided Sleeve?

In swimming pool filtration and dosing systems, engineers commonly need a container that allows water to pass through while holding granular disinfectants such as lime or chlorine.

Traditionally, they rely on:

- perforated plastic tubes

- stainless-steel mesh baskets

- plastic mesh bags

- molded filter cartridges

These products work — but they also come with limitations.

This is why more engineers are switching to tight weave braided sleeve, especially for large-volume granular media.

Superior Mesh Precision: Designed Apertures, Not Random Holes

Plastic mesh bags or punched tubes often have inconsistent hole sizes or rough edges.

Controlled Apertures

A tight weave braided sleeve is different,Its aperture is controlled by,Its aperture is controlled by:

- yarn diameter

- braid angle

- number of carriers

- applied tension during weaving

Key Advantages

This results in:

- water flows freely

- granules stay securely inside

This level of precision is nearly impossible to achieve with low-cost mesh bags or perforated tubes.

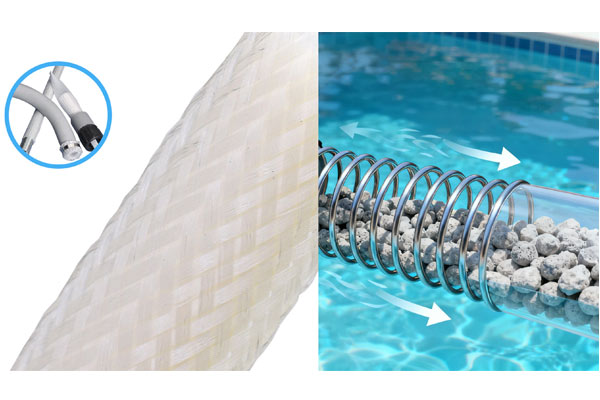

Expansion Capability: Something No Rigid Mesh Can Do

Traditional mesh filters are fixed in size.But a braided sleeve can expand dramatically when shortened:

Expansion Advantages

- expands up to 100–150 mm

- fits large metal springs inside

- holds more granular media without increasing material cost

- keeps the structure lightweight and flexible

Rigid plastic filters cannot match this adaptability.

Structural Stability Under Water Pressure

Pool circulation systems constantly generate shifting water pressure.Traditional mesh bags may collapse or fold under pressure.

Why Braided Sleeves Stay Stable

A tight weave braided sleeve maintains shape because:

- the braid distributes stress evenly

- PET fiber has excellent elastic memory

- an internal spring provides constant support

It bends but does not collapse — a key advantage for consistent dissolving performance.

Material Compatibility: PET + Stainless Steel = Perfect Match

Many mesh bags degrade when touching chemicals or metals.

PET and Stainless Steel Advantages

But PET braided sleeves work exceptionally well with stainless-steel springs:

- no chemical reaction

- no galvanic corrosion

- fibers do not fray or wear out

- the sleeve stays in position without slipping

This makes the structure durable enough for long-term submersion.

Why Engineers Ultimately Choose the Tight Weave Braided Sleeve

From a materials science and engineering standpoint, it solves multiple requirements at once:

Key Engineering Advantages

| Engineering Need | Tight Weave Braided Sleeve Advantage |

| Water permeability | Precisely controlled mesh structure |

| Chemical resistance | PET stable in alkaline conditions |

| Flexibility | Adapts to various installation spaces |

| Large media capacity | Expandable diameter |

| No particle leakage | Adjustable mesh density |

| Low cost | No mold, no machining, lightweight |

Instead of relying on rigid structures, engineers get a smart, adaptable, chemical-resistant, cost-effective solution.