As Europe enters its summer break, a shift occurs not only in business rhythms but also in how projects are approached—especially in industries like facility maintenance, small-batch assembly, field upgrades, and public infrastructure. While some factories slow down, many technical teams, subcontractors, and installers use this period to complete critical wiring jobs, often relying on solutions like self closing braided wrap to ensure fast, clean, and tool-free cable protection.

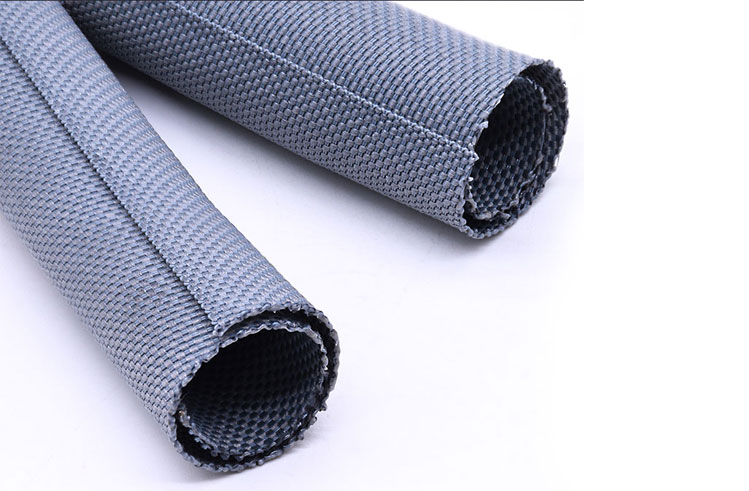

Our self-closing Braided Sleeve, a UL94 V0-rated polyester wrap with expandable design and fast cable access.

1.Facility Electrical Retrofits During Shutdowns

Many factories, universities, and public buildings in France, Germany, and Italy schedule electrical maintenance during the summer when the buildings are partially or fully shut down. This creates a limited time window where cable upgrades must be fast, efficient, and safe.

Why braided sleeves?

Pre-cut self-closing sleeves allow electricians to wrap around cables without disconnecting them, saving time and reducing the risk of damaging sensitive systems.

Potential challenge:

Some sleeves fray at the edges if not cut cleanly. Be sure to request laser-cut or heat-sealed ends—especially when ordering custom lengths.

Self-closing braided wraps are ideal for quickly reinforcing worn harnesses or adding additional cable runs without dismantling panels.

In tight engine compartments or door panels, sleeves with insufficient expansion won’t fit. For this, a 10mm ID with 50mm expansion range, ensures enough flexibility.

2.Solar and Outdoor Installations in Southern Europe

Installers in Spain, Portugal, and Greece often work on solar farms, telecom relays, or smart energy devices during dry summer months. But high temperatures and open-air environments expose cables to UV, abrasion, and shifting loads.

Why this sleeve?

It not only protects against mechanical wear and moderate chemical exposure, but its self-wrapping nature means it can expand around connectors and irregular shapes.

Possible concern:

If exposed to direct UV for extended periods, PET-based sleeves may degrade over time. We recommend using UV-resistant versions or housing them in protected conduits when possible.

Packaging & Delivery Consideration

Many clients during this period prefer pre-cut-to-length options over reels because:

There’s less time for manual cutting in the field.

It reduces setup time for subcontractors or temp workers hired during the summer.

Logistics note:

Ensure your supplier can clearly label and package segments by length. Poor handling during customs or transport in high heat can deform soft materials.

Final Tips for Summer Procurement Teams

Order at least 2–3 weeks before your planned shutdown to avoid delays from port congestion or summer workforce shortages.

Discuss custom-cutting services with your supplier to match your installation plan.

Confirm whether sleeves are laser-cut to avoid fraying on site.

Self-closing braided sleeving offers a smart, flexible solution for wiring upgrades, especially during Europe’s complex summer schedule. Whether you’re upgrading a control cabinet, retrofitting metro signal cables, or protecting new solar installs, choosing the right format, expansion ratio, and cut length makes all the difference.

Summer may slow down offices—but field projects continue. Make sure your cable protection doesn’t take a vacation.