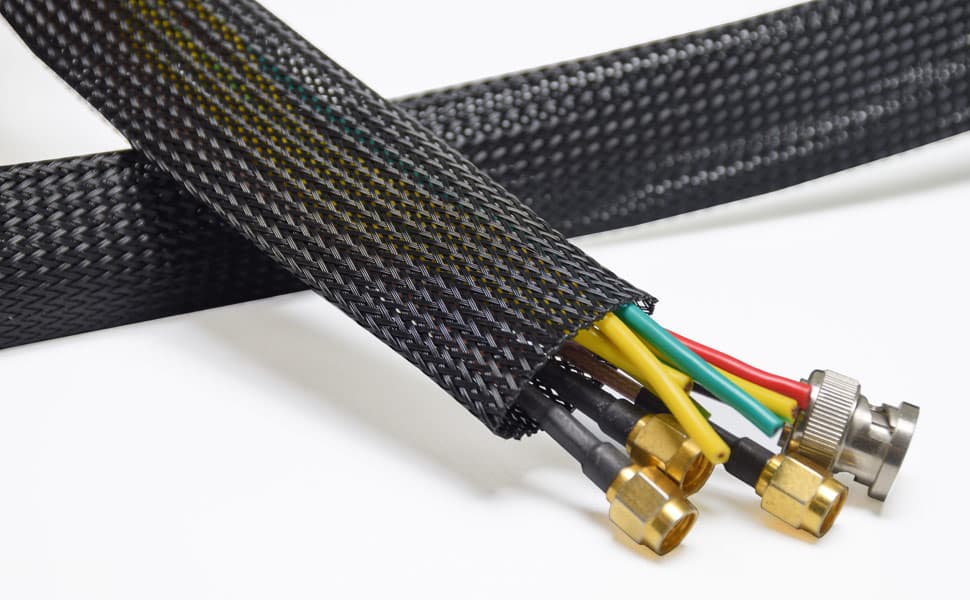

What is Expandable Braided Mesh Sleeving?

Expandable braided sleeving is a versatile cable management solution used to protect and organize wire harnesses. Its open-weave design allows for easy inspection and individual wire removal while maintaining flexibility and durability. Unlike solid tubing, it adds minimal weight or bulk, making it ideal for automotive, aerospace, and industrial applications.

Why Choose Expandable Sleeving?

- Flexibility & Adaptability: Conforms to complex shapes without restricting movement.

- Material Options: Available in nylon, PPS (polyphenylene sulfide), polyester, and Nomex®—each offering abrasion resistance and high-temperature stability.

- Ease of Use: Quick installation without requiring harness disassembly.

The Best Way to Cut Braided Sleeving: The Hot Knife Method

To prevent frayed edges, a hot knife is the most efficient tool for cutting expandable braided mesh cable sleeve, especially polyester-based sleeves.

What is a Hot Knife?

A hot knife features a heated metal blade that melts through synthetic fibers, sealing the edges simultaneously. This prevents unraveling and speeds up production by allowing pre-cut lengths to be stored for future use.

Step-by-Step Cutting Guide

- Measure Accurately:

- Lay the sleeving loosely over the intended application (avoid stretching, as it may shorten when expanded).

- Mark the cutting line with a marker.

- Cut with Precision:

- Heat the knife to the recommended temperature for the material (e.g., ~300°F for polyester).

- Practice on scrap sleeving first to gauge the cutting speed.

- Work in a well-ventilated area to avoid inhaling fumes.

- Flare the Ends (Optional):

- While the cut end is still warm, use an inverted funnel, scissors, or needle-nose pliers to create a soft flared opening. This eases installation over connectors.

- Install the Sleeving:

- Slide the flared end onto the wire bundle, then adjust the sleeving along the harness.

- Smooth by hand for a secure fit.

Alternative Fray-Free Termination Methods

- Tape Wrap:

- Fast and economical. Use color-matched tape to tightly bind the ends.

- Cable Ties:

- Provides a secure, low-cost solution with color-matching options. Ideal for minimal-rework applications.

- Heat-Shrink Tubing:

- Offers superior protection against moisture and heat. Requires a heat gun but is preferred in automotive/aerospace industries.