Products

New Products

-

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5

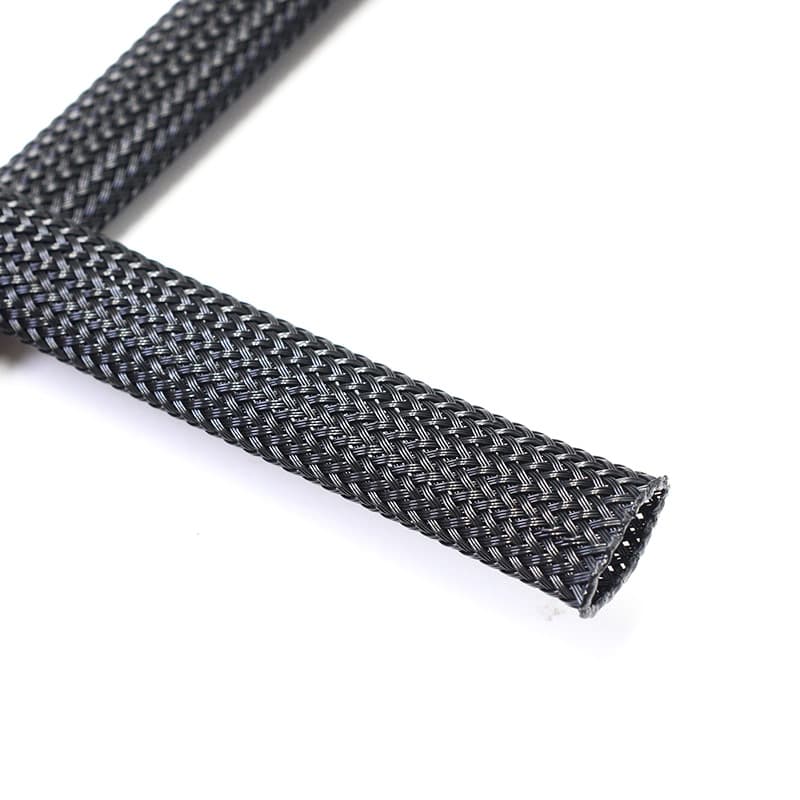

Abrasion and Flame Retardant Tight Weave Braided Sleeve

Flame retardant tight weave PET braided sleeving offers superior flame resistance and abrasion protection. Made from tightly woven PET monofilament, it provides seamless coverage, reduces weight, and ensures durability. Ideal for aerospace, automotive, military, and industrial applications, this sleeving excels in demanding environments where fire protection and reliability are critical. Available in various sizes to fit different wire harnesses.

| Part No | BRS-PET-HD-FR-HA |

|---|---|

| Material | PET monofilament |

| Filament Dia | 0.25mm(0.01”) |

| Working Temperature | -40℃~+150℃ |

| Melt Point | 240+(-)10℃ |

| Low Temperature Tesistance | No signs of embrittlement or degradation after test at -40℃ for 4h |

| Heat Aging Resistance | No signs of embrittlement or degradation after test at158℃ for 168h |

| Flammability | FMVSS302,UL94 V0 |

| Certification | Rohs,Reach,HalogenFree |

Wear and Flame Retardant Tight Weave Braided Sleeve

E-FLEX® FR flame retardant tight weave sleeving PET braided sleeving is braided from 0.25mm PET monofilament. The tightly woven design significantly enhances coverage, abrasion resistance, and wear performance, ensuring superior security in any wire harness or cable bundle. This sleeve is particularly suitable for applications where a balance between cost, optimal coverage, flame retardancy, and abrasion resistance is essential.

As a premium upgrade to standard flame-retardant sleeving, Available in multiple sizes to fit various wire harness diameters, it’s specifically engineered for weight-sensitive environments where both safety and performance are critical.

The Feature of Wear and Flame Retardant Tight Weave Braided Sleeve

- Superior Coverage – Tightly woven flame-retardant monofilament provides full, seamless protection for wire harnesses, minimizing exposure to abrasion and debris.

- Lightweight Design – Engineered to reduce weight while maintaining durability—ideal for weight-sensitive aerospace applications.

- Enhanced Flame Resistance – Meets stringent aviation safety standards, offering reliable fire protection for high-risk environments.

- Wide Compatibility – Available in multiple sizes.

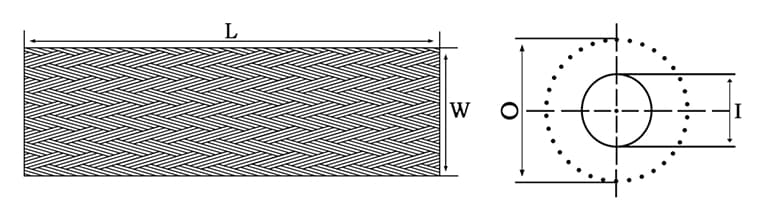

Product Size

| Part No | Flat Width(W) | Expanded Range(mm) | Wall Thickness (mm) | Packing Length (m/spool) | ||

|---|---|---|---|---|---|---|

| Inch | mm | Min.(l) | Max.(O) | |||

| BRS-PET-006-BK-HD-FR-HA | 1/4″ | 6 | 5 | 8 | 0.85±0.05 | 400 |

| BRS-PET-008-BK-HD-FR-HA | 5/16″ | 8 | 6 | 10 | 0.85±0.05 | 300 |

| BRS-PET-009-BK-HD-FR-HA | 9/25″ | 9 | 8 | 12 | 0.85±0.05 | 300 |

| BRS-PET-010-BK-HD-FR-HA | 3/8″ | 10 | 9 | 15 | 0.85±0.05 | 300 |

Application

Flame Retardant Tight Weave Sleeving is ideal for use in environments that demand superior durability, flame resistance, and lightweight materials. It is now widely used across various high-performance applications, including:

- Aerospace and Aviation – Protects critical wire harnesses in aircraft cabins, cockpits, and engine compartments, where flame resistance and weight reduction are essential.

- Railway and Transportation – Ensures long-lasting cable protection in trains, subways, and commercial vehicles subjected to constant vibration and friction.

- Military and Defense Systems – Used in mission-critical communication and control systems to protect sensitive wiring under extreme conditions.

- Industrial Automation – Provides reliable shielding for control cables and power lines in factories, robotics, and automated machinery.

- Marine Applications – Safeguards wiring against environmental wear and fire risks in boats, ships, and offshore platforms.