Products

New Products

-

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5 -

Rated 0 out of 5

Rated 0 out of 5

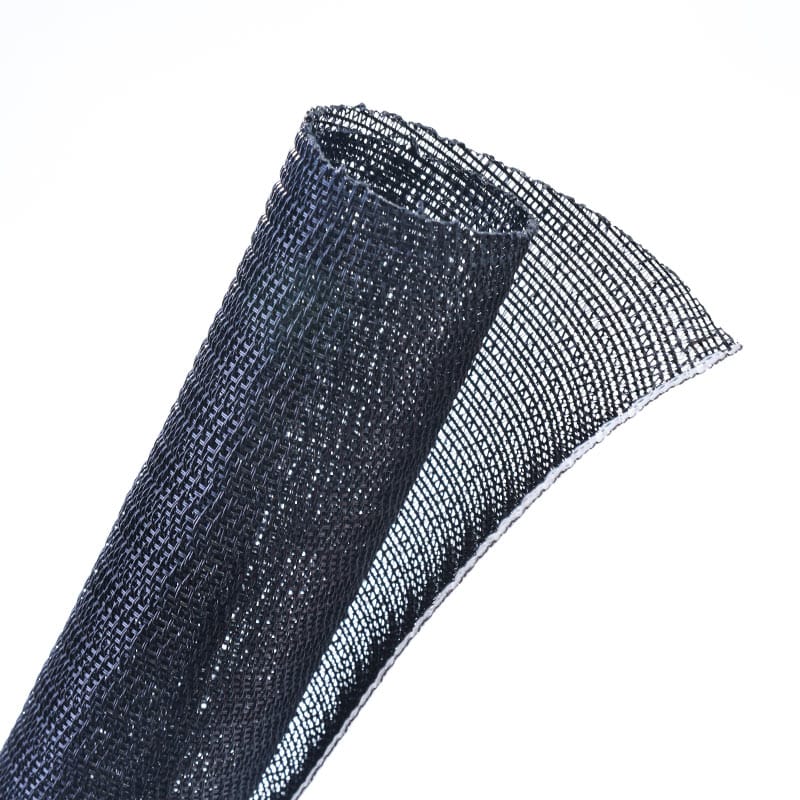

White Edge Polyester Monofilament Split Cable Sleeve

The white edge polyester monofilament split cable sleeve provides reliable protection for wire harnesses and hoses in railway and automotive applications. With its flame-retardant and durable design, this sleeving offers excellent heat dispersion and abrasion resistance. The self-closing feature allows for easy installation, making it an ideal choice for maintaining safety and performance in demanding environments.

| Part No | STW-PES |

|---|---|

| Material | Polyester |

| Working Temperature | -40℃ to 125℃ |

| Melt Point | 240±10℃ |

| Flammability | Refer to DIN5510, accord with S-4 SR-2 ST-2 grade |

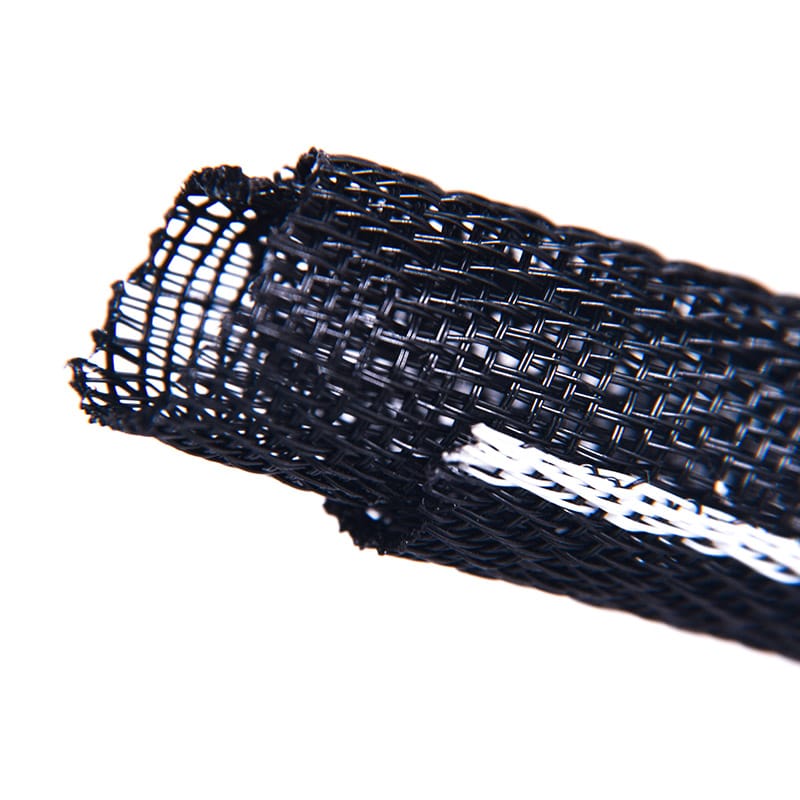

| Standard Color | Black with White Identification Line |

| Abrasion Resistance | Refer to GMW14327(ISO6722-1) ,>1462 times. |

| Low temperature resistance | Refer to GB/T 2423.1, after -50℃/4H test,there should be no visible change in appearance,Stretching (or bending) operation, there should be no damage and broken wire. |

| Heat resistance | Refer to GB/T 2423.2, after 150℃/24H test, there should be no visual change in appearance, stretching (or bending) operation,there should be no damage and wire breakage. |

| Cutting Tool | Hot Knife |

White Edge Polyester Monofilament Split Cable Sleeving

The white edge polyester split braided cable sleeve is an innovative protective solution designed to safeguard cables and wires in various applications. This sleeving features a durable polyester monofilament construction with a distinctive white edge, ensuring enhanced visibility and aesthetics. Its split design allows for easy installation over existing cables, providing excellent abrasion resistance while maintaining flexibility.

This cable sleeve meets environmental standards, including RoHS and REACH certifications, making it an eco-friendly choice for industries prioritizing sustainability. Its soft and adaptable structure protects against wear and tear, making it ideal for applications in automotive, railway, and machinery sectors.

With its superior protection capabilities and stylish appearance, the white edge polyester monofilament split cable sleeve is perfect for ensuring the longevity and integrity of your wiring systems while contributing to a cleaner and safer environment.

Certifications

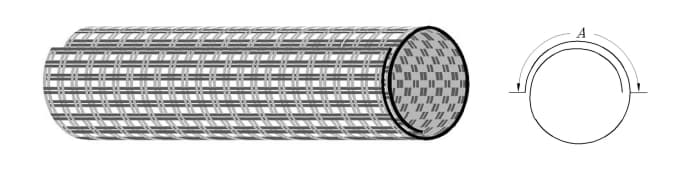

Product Size

| Part No | Nominal Diameter (mm) |

Recommended Application Range |

Thickness (mm) |

Packing Length (m/spool) |

|

|---|---|---|---|---|---|

| Min | Max ① | ||||

| STW-PES-005-BK | 5 | 1 | 5 | 0.7+0.15 | 100 |

| STW-PES-008-BK | 8 | 6 | 8 | 0.7+0.15 | 100 |

| STW-PES-013-BK | 13 | 9 | 13 | 0.7±0.15 | 100 |

| STW-PES-016-BK | 16 | 13 | 16 | 0.7±0.15 | 50 |

| STW-PES-019-BK | 19 | 14 | 19 | 0.7±0.15 | 50 |

| STW-PES-025-BK | 25 | 20 | 25 | 0.7±0.15 | 25 |

| STW-PES-029-BK | 29 | 26 | 29 | 0.7±0.15 | 25 |

| STW-PES-032-BK | 32 | 30 | 32 | 0.7±0.15 | 25 |

| STW-PES-038-BK | 38 | 33 | 38 | 0.7+0.15 | 25 |

| STW-PES-050-BK | 50 | 39 | 50 | 0.7±0.15 | 25 |

Application

The white edge polyester self-closing wrap is widely utilized in various industries, particularly in the railway and automotive sectors. In these applications, wire harnesses and hoses face demanding conditions that require robust protection against heat, flames, and abrasion.

In the railway industry, this sleeving provides essential safety features by enhancing flame retardancy and heat dispersion, ensuring that critical wiring systems remain operational in high-temperature environments. Its self-closing design facilitates easy installation over existing cables, making maintenance and retrofitting more efficient. This is especially important in rail vehicles, where reliability and safety are paramount.

In the automotive sector, the sleeving protects wires and hoses from abrasion, moisture, and chemical exposure, contributing to the longevity of electrical systems and components. The visibility provided by the white edge helps in identifying wiring during inspections, improving overall safety. Moreover, its lightweight yet durable construction aids in enhancing vehicle performance by reducing weight without compromising on protection.

Additionally, this versatile sleeving finds applications in machinery and industrial equipment, where it safeguards cables in environments that may involve exposure to oils, solvents, or other harsh substances. Its compliance with environmental standards like RoHS and REACH further emphasizes its suitability for industries focused on sustainable practices.

Overall, the White Edge Polyester Monofilament Split Cable Sleeve is an essential component in ensuring the reliability and safety of wiring systems across multiple high-demand applications, making it a preferred choice for engineers and manufacturers alike.