When it comes to evaluating the safety and quality of plastic-based products—especially in applications like braided cable sleeves, wire harness protection, or insulation covers—flammability testing is a vital step.

The flammability test is not just about whether a material burns, but how it behaves during combustion. This allows engineers, manufacturers, and quality controllers to determine whether the plastic is self-extinguishing, highly flammable, or releases harmful smoke or odor.

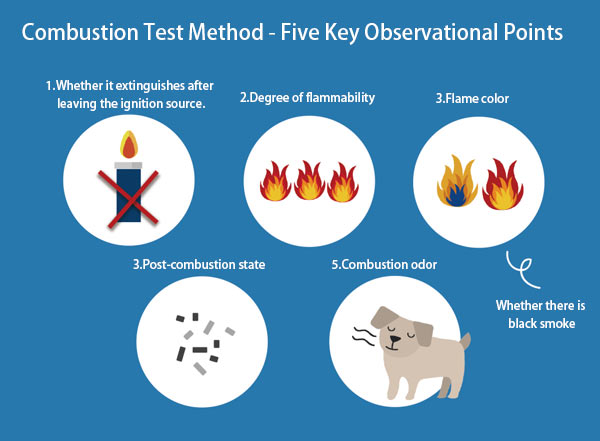

The 5 Key Observations in a Flammability Test

The following criteria should be assessed when performing a flame test on plastic materials used in wire harness protection applications.

Extinguishing Behavior

Does the material stop burning when the flame source is removed?

This determines if the material is self-extinguishing (a key requirement for UL 94 V0 or FMVSS 302).

Flammability Level

How easily does the material catch fire and how rapidly does it burn?

Materials with lower ignition points may not be suitable for automotive or industrial use.

Flame Color

What is the color of the flame—blue, yellow, red, or smoky?

Different plastic families exhibit specific flame hues that can indicate chemical composition (e.g., PVC burns with a green hue).

Post-Burn Residue

Does the material drip, char, or melt? What is the texture of the residue?

For example, PET typically leaves carbonized black ash, while polyolefins may melt and drip.

Smoke and Odor

Does it emit black smoke? Is there a strong, irritating odor?

A pungent or toxic smell indicates the release of hazardous gases, which must be evaluated for compliance with environmental standards (e.g., RoHS, REACH).

Why Is This Important for Braided Sleeving & Wire Harnesses?

Products like PET braided sleeving, PA expandable sleeves, or fiberglass-based high-temp sleeves are often used in:

- Automotive wiring harnesses

- Electrical cabinet assemblies

- Industrial automation systems

For these applications, materials must not only provide mechanical protection but also meet fire safety standards. Conducting a flammability test helps determine if your sleeving:

- Meets UL 94 or FMVSS 302 fire resistance ratings

- Is halogen-free or low-smoke emitting (LSZH)

- Can be safely used in vehicle cabins, control panels, or engine bays

| Observation Point | What to Look For |

| Self-extinguishing? | Yes = safer material |

| Flame color | Clear indication of material class |

| Smoke level | Thick black = possible toxic resin |

| Odor | Strong odor = consider alternatives |

| Residue | Dripping? Ashy? Indicates polymer |

Note: Always conduct flame tests in controlled environments, and refer to certified lab results when necessary.