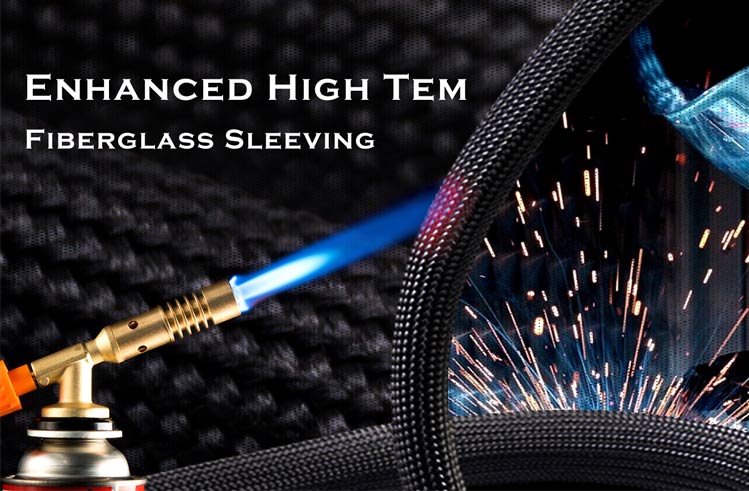

Next-Gen Fiberglass Sleeving for High-Heat Cable Protection in EVs, Energy & Automation

With global industries accelerating toward decarbonization, electrification, and intelligent automation, the demand for durable, flame-resistant cable protection has intensified. To meet today’s demanding conditions, enhanced fiberglass sleeving has emerged as a next-gen material for safeguarding cables in high-heat, high-risk environments.

Why Enhanced Fiberglass Sleeving Is Gaining Momentum

In sectors like electric mobility, renewable energy, and industrial automation, cables are frequently exposed to extreme temperatures, vibration, chemicals, and mechanical stress. This creates an urgent need for insulation materials that can maintain integrity under pressure.

Constructed from durable fiberglass and coated with heat-resistant polymers, enhanced sleeving withstands extreme temperatures—often exceeding 550°C. In addition to providing mechanical toughness and electrical insulation, its structure also meets key safety and environmental standards, including UL 1441, CSA, and RoHS.

Key Features:

- Flame Retardant: Slows down or halts the spread of fire

- High Thermal Resistance: Performs reliably in extreme heat

- Excellent Electrical Insulation: Prevents arcing or short circuits

- Chemical & Abrasion Resistant: Withstands oils, solvents, and friction

- Flexible & Easy to Install: Ideal for complex cable assemblies

Where It’s Used – Real-World Applications

Electric Vehicles (EVs):

Battery compartments and powertrain systems require robust insulation to prevent thermal events.

Solar & Wind Power Systems:

Inverters, control panels, and grid connections are often exposed to outdoor heat and electrical surges.

Industrial Robotics & Automation:

Robots and production lines run continuously, generating heat and wear that demand long-life cable protection.

Rail, Aerospace & Defense:

Designed for confined, high-heat environments, fiberglass sleeving ensures compliance with tough fire and safety codes.

A Timely Solution for Global Demands

In 2025, as more governments implement stricter safety regulations (such as EN 45545 for transportation and NFPA 79 for industrial machinery), companies are re-evaluating their material choices. Enhanced fiberglass sleeving is a compliant, tested solution that ensures both safety and performance without sacrificing ease of use.

Amid global transitions in clean energy and smart infrastructure, it is no longer enough to simply protect cables—it’s about ensuring operational continuity in any environment.

Whether you’re manufacturing electric buses, building solar farms, or upgrading industrial machinery, enhanced fiberglass sleeving stands as a future-proof investment. Engineers around the world rely on its exceptional heat resistance and protective performance.

For durable, high-temperature cable protection—fiberglass sleeving is not just an option, it’s the standard.